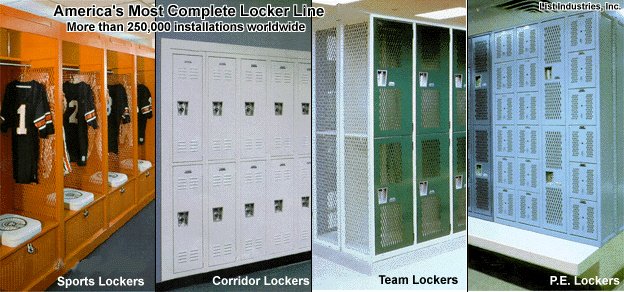

Lockers:

We provide lockers for virtually all applications.

From entry level, to practically indestructible,

we have them all. Below is an easy class guide

to understand quality differences between

various lockers.

Fully-Framed All-Welded Lockers

SUPERIOR™

Fully-Framed All-Welded Athletic Lockers

Features and Options

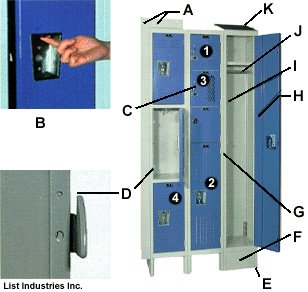

Introducing … Two-Tone Color Combinations Optional at no additional

cost for all lockers. Frame one color and doors a second color. Feel free

to choose from any of our 24 standard colors.

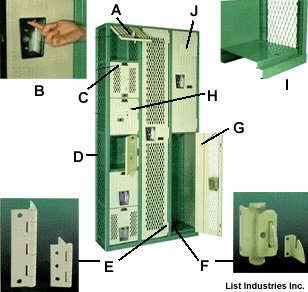

Continuous 16 gauge Flat Top – Optional continuous slope top

available.

Ventilated Shelves – Diamond perforations allow air to flow thru

shelf. Available as an option at a slight additional charge (not shown).

A. Heavy-Duty Spring Latch – Self-closing with stainless steel

spring. Standard on all gym doors.

B. Stainless Steel Recessed Handle – Standard in single, double

and triple tier wardrobe lockers. Optional for top hinged gym doors (padlock

use

only) at an upcharge.

C. Safety Minded Top Hinged Gym Doors – Self-closing when not

in use. Continuous hinge safely concealed.

D. Ventilated Sides – 13 gauge flattened expanded metal protected

and fully-framed by our unique Hollow-T framing system.

E. What A Difference – Between Our 13 gauge, 3-1/2" 7-knuckle

hinge vs. common 2" K.D. locker style hinge.

F. The Industry's Best – Our rugged 11 gauge MIG welded latch

hook with large riveted bumper vs. common K.D. locker style latch hook.

G. Full Height Door Stiffener – Standard for all doors 20"

high and above that are over 15" wide. Available as an option on

other doors.

H. Side Hinged Gym Doors – Available for gym doors with projecting

spring latch only. (No charge.)

I. 14 gauge Integral Channel Base – Places locker bottom 2-3/4"

above finished floor. (Optional 4" high metal base available at a

nominal

upcharge.)

J. Optional Armor Vent Security Perforated Doors – Also optional

louvered or solid. Additional charges may apply. Diamond perforations

are standard.

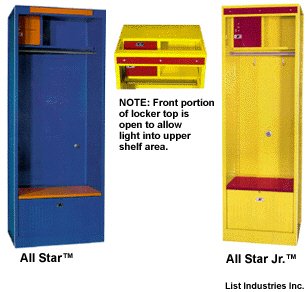

All Star & All Star Jr. Lockers

List Industries Inc.™

The Ultimate Sports Locker

Originally custom designed for the University of Georgia varsity football

program, the All Star Locker has become the measuring stick against which

all other sports lockers are measured. The versatility of this open front

design has enabled it to become the premier sports locker in the industry.

All Star™

Features:

- Fully-Framed All-Welded construction

- Electrogalvanized sheet steel components to resist corrosion

- Open-front design for ventilation

- Foot locker doubles as a seat

- Security box w/ mail slot (equipped for built-in lock or padlock)

- Integral 4" metal base for mounting directly to finished floor

- Armor-Vent security perforations at foot locker and security box

- Half-depth shelf for added head room

- Partial-open-top design to allow light into upper locker area (center

photo)

- Lifetime warranty

Equipment:

- Stainless steel clothes rod

- Card-holder for player's name

- (2) Coat hooks at rear

- Mirror (field attached, not shown)

- Rear bumpers to cushion foot locker seat when open

- Padlock strike plates to protect finish from marring

Dimensions:

The All Star is an immense 33" wide x 22" deep x 84" high

The Tradition Lives On

All Star Jr.™

The All Star Jr. Locker is the little brother of the full size All

Star. The construction and features are exactly the same except the size.

Our most popular sports locker is widely used in high school and collegiate

sports programs across the globe.

Dimensions: 24" w x 22" d x 74-3/4" h. (Nominal width)

Fully-Framed All-Welded All-Star and All-Star Jr.

Sports Locker Specifications

PART 2 - PRODUCTS

MATERIALS

Expanded Metal: 3/4" mesh flattened carbon steel, 10 gauge minimum.

Steel: All sheet steel used in fabrication shall be prime grade electrogalvanized

steel free from scale and imperfections and capable of taking a heavy

coat of high gloss baked enamel.

Fasteners: Zinc plated steel; bolt heads to be slotless type.

Equipment: Hooks of zinc plated steel. Hang rods to be Stainless Steel.

Number Plates: To be polished aluminum with not less than 3/8"

high engraved numbers attached to door with two aluminum rivets. Numerals

to be silver on black background.

FABRICATION:

GENERAL: All lockers shall be factory-assembled, of all MIG welded

construction, in multiple column units to meet job conditions. All locker

components shall be fabricated from prime grade Electrogalvanized steel.

Assembly of locker bodies by means of bolts, screws, or rivets will not

be permitted. Welding of knockdown locker construction is not acceptable.

Grind exposed welds and metal edges flush and make safe to touch.

FINISHING: All locker parts to be cleaned and coated after fabrication

with a seven stage zinc/iron phosphate solution to inhibit corrosion,

followed by a coat of high grade enamel electrostatically sprayed and

baked at 325 degrees Fahrenheit for a minimum of 30 minutes to provide

a tough durable finish.

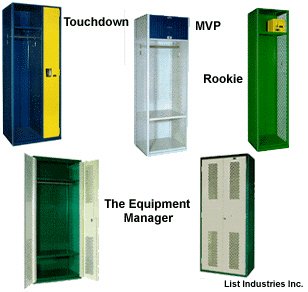

Touchdown, MVP, Rookie, & Equipment

Manager Lockers

List Industries Inc.™

Originally a custom design for the University of Michigan Wolverine

football program, we created this all purpose sports locker. Providing

a 12" wide clean area for clothes while leaving an ample 18"

wide open ventilated space for sports gear, no locker in the industry

accomplishes this feat better than our Touchdown Locker.

Equipment: Hat shelf, stainless steel clothes rod and two wall hooks

included in both 12" and 18" wide compartments.

Dimensions: 30-5/8" w x 22" d x 74-3/4" h. Other sizes

available upon request.

MVP

This locker was designed exclusively for the University of Cincinnati

Bearcat varsity football program and has evolved into what we now call

our MVP. The MVP has a large ventilated space for all the athletes' gear

and a large lockable security compartment for their valuables. The lower

shelf doubles as a seat. Wood seat is optional.

Dimensions: Available in all single tier welded locker sizes.

Rookie

The Rookie is an old favorite of ours. Its design is simple, yet very

practical. We start with a standard single tier locker and remove the

door to provide a maximum amount of ventilation. The sides are 13 gauge

flattened expanded metal (solid sides are available at an upcharge). Shown

with optional security box (7-1/4" w 9" d x 7-1/4" h).

Equipment: One hat shelf, four single hooks and one double hook.

Dimensions: Available in all single tier welded locker sizes.

The Equipment Manager

Designed to be the solution to all your storage problems. The Equipment

Manager is a secure, attractive work of engineering excellence.

- Hollow-T fully-framed all-welded construction

- 13 gauge flattened expanded metal sides

- 14 gauge diamond perforated doors

- 18 gauge full height door stiffeners

- 3-point turn handle latching

- Upper shelf located 12" down from the top

- Lower shelf located 18" up from the bottom

- Stainless steel clothes rod

- Clothes hooks

Dimensions: 36-1/2" w x 22" d x 84" h.

Fully-Framed All-Welded Sports Locker Specifications

MATERIALS

Steel Sheet: All sheet steel used in fabrication shall be prime grade

free from scale and imperfections and capable of taking a heavy coat of

high gloss baked enamel.

Expanded Metal: 3/4" mesh flattened carbon steel, 13 gauge minimum.

Stainless Steel: 304 stainless steel with no.4 finish shall be used

for all recessed handles and lock hole cover plates.

Electrogalvanized Sheet Steel: Shall be used for all hat shelves,

intermediate shelves and bottoms.

Fasteners: Zinc plated steel; bolt heads to be slotless type.

Equipment: Hooks and hang rods of zinc plated steel.

Number Plates: To be polished aluminum with not less than 3/8"

high engraved numbers attached to door with two aluminum rivets. Numerals

to be silver on black background.

GENERAL: Lockers shall be SUPERIOR FULLY-FRAMED ALL-WELDED SPORTS

LOCKERS as manufactured by List Industries Inc. All lockers shall be factory-assembled,

of all MIG welded construction, in multiple column units up to 60"

wide to meet job conditions. Assembly of locker bodies by means of bolts,

screws or rivets will not be permitted. Welding of knock-down locker construction

is not acceptable. Grind exposed welds and metal edges flush and make

safe to touch.

FINISHING: All surfaces shall be thoroughly cleaned with a seven stage

hot-spray washing process and coated with an insoluble iron phosphate

film to inhibit corrosion, followed by a coat of high grade enamel electrostatically

sprayed and baked at 350 degrees Fahrenheit for a minimum of 20 minutes

to provide a tough durable finish. Color to be selected from our 24 standard

colors. Two-tone color combination (frame one color and the doors a second

color) is available at no additional cost.

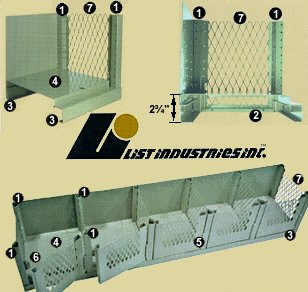

FRAME / VERTICAL SIDE PANELS: Shall be of 13 gauge 3/4" flattened

expanded metal fully-framed and completely enclosed on all four sides

by two 16 gauge vertical Hollow-T tubular sections and two 16 gauge double

channel horizontal frame members. The entire sub-assembly shall be MIG

welded to the 14 gauge horizontal channel base creating a full frame at

front, back, top and bottom of each multiple column locker unit.

HORIZONTAL CHANNEL BASE: 14 gauge formed structural channels are MIG

welded to the front and rear vertical side panel frame members to allow

placement of locker bottom 2-3/4" above floor level. Base channels

to be continuous across the full unit width at front and back of each

multiple column locker unit.

WARDROBE DOORS (Where Applicable): Doors 20" high and over to

be fabricated from single sheet prime 14 gauge with single bends at top

and bottom and double bends at the sides. The channel formed by the double

bend at the latch side is designed to conceal the lock bar. Doors over

15" wide x 20" high shall include an 18 gauge full height door

stiffener MIG welded to the hinge side as well as the top and bottom door

flanges. The latching mechanism shall be finger lift control type constructed

of 12 gauge (minimum) steel with a nylon cover that has a generous finger

lift. Spring activated nylon slide latches shall be completely enclosed

in the lock channel allowing doors to close with the lock in the locked

position. Locking device shall be designed for use with either built-in

combination locks or padlocks. Latch hooks shall be 11 gauge (minimum)

with riveted bumpers and shall be MIG welded to vertical frame member.

Provide three latch hooks for doors 48" high and over and two for

doors under 48" high. Doors to be diamond perforated for maximum

ventilation.

GYM DOORS (Where Applicable): Doors 18" high and under to be

fabricated from single sheet prime 14 gauge with single bend at top &

sides and double bend at latch point (bottom). An 11 gauge spring loaded

latch assembly shall be securely welded to the inside of the door. The

latch shall be equipped with a stainless steel spring and shall automatically

engage when door is closed. Rubber bumpers shall be riveted to return

bends on doors. Locking device shall be designed for use with padlock

or built-in lock. Doors to be diamond perforated for maximum ventilation.

LOCKER HANDLE: All wardrobe doors shall have recessed stainless steel

handle shaped to receive a padlock or built-in combination lock. The recessed

pan shall be deep enough to have the lock be flush with the outer door

face. Door face to be embossed to allow recessed handle to be mounted

completely flush with outer door surface.

DOOR HINGES: Hinges for doors (15" high and over) shall not be

less than 3-1/2" long 13 gauge seven knuckle pin type, securely riveted

to frame and welded to the door. Doors are to be secured to frame with

a minimum of two tamper resistant rivets per hinge. Provide 3 hinges for

doors 48" and higher and 2 for doors shorter than 48". Top hinged

gym doors 12" high and under shall be hinged using a 3/16" diameter

continuous hinge rod completely recessed into the door with a concealed

fastener.

FLAT TOPS: Shall be formed of one piece 16 gauge cold rolled sheet

steel as an integral part MIG welded to each vertical side panel frame

member and be continuous to cover the full width of a multiple locker

unit.

HAT SHELVES, INTERMEDIATE SHELVES AND BOTTOMS: Shall be 16 gauge electrogalvanized

steel, have double bends at front and shall engage slots in the Hollow-T

vertical frame members at all four corners and be securely welded to the

frame and side.

BACKS: Shall be 18 gauge cold rolled sheet steel fabricated to cover

a multiple framed unit and welded to each vertical side panel frame member.

P.E. & Combination Lockers

List Industries Inc.™

Combination gym and wardrobe units are usually found in P.E. locker

rooms where the smaller gym locker is permanently assigned and the larger

wardrobe locker is used by a student only during the class period. There

are unlimited methods of achieving desired gym locker to wardrobe locker

ratios. Please note that the actual units supplied will be fabricated

to meet layout and job conditions in standard width units up to six columns

wide (maximum 60").

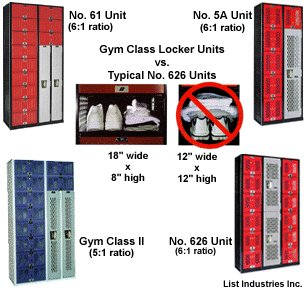

Gym Class Locker Units vs. Typical No. 626 Units

- Maximizes ventilation for clothing and shoes

- Increases shelf space by 50%

- Adds 12" in height to wardrobe opening

- Places one gym locker at unit bottom in lieu of two

- 3 latch points and 3 hinges per wardrobe door in lieu of 2

Gym Class (6:1 ratio)

This unit, also known as the "9E Unit" is a favorite among

architects and school authorities across the country. The overwhelming

conclusion is that shelf space is more effective in achieving maximum

ventilation than height in a gym locker. SUPERIOR™ Gym Class lockers

accommodate 12 students in a compact three lineal feet of space utilizing

the popular 6:1 ratio replacing the typical "626" combination.

Each gym locker is a full 18" wide x 8" high. The wardrobe lockers

are 9" wide x 48" high.

Standard unit sizes: 36-3/8" wide x (12", 16", 18"

& 22") deep x 74-3/4" high.

Gym Class II (5:1 ratio)

SUPERIOR™ Gym Class II Lockers, also known as "8D Units"

are designed with the same premise as its big brother, the Gym Class.

We have engineered the finest 5:1 ratio unit in the locker industry utilizing

the same floor space as a standard "525" configuration. This

locker is actually 64" high nominal as opposed to 60". Like

the Gym Class, gym doors are 18" wide x 8" high and the wardrobe

doors are 9" wide x 48" high.

Standard unit sizes: 36-3/8" wide x (12", 16", 18"

& 22") deep x 66-3/4" high.

Sizes for Gym Lockers

Widths for all gym locker openings: 12", 15", 18"

Depths for all gym locker openings: 12", 16", 18", 22"

Four Tier

Opening Heights: 8", 9", 12", 15", 18"

Nominal Column Heights: 32", 36", 48", 60", 72"

Five Tier

Opening Height: 12"

Nominal Column Height: 60"

Six Tier

Opening Heights: 8", 10", 12"

Nominal Column Heights: 48", 60", 72"

Seven Tier

Opening Heights: (6) 10" & (1) 12" only

Nominal Column Height: 72"

Eight Tier

Opening Heights: 8", 9"

Nominal Column Heights: 64", 72"

Nine Tier

Opening Height: 8"

Nominal Column Height: 72"

K.D. Locker Features and Options

List Industries Inc.™

Superior™ Standard Quiet, Classic & HDV K.D. Lockers

Features and Options

Introducing…Two-Tone Color Combinations Optional at no additional

cost for all lockers. Frame one color and doors a second color. Feel free

to choose from any of our 24 standard colors.

A. Top and Side Recessed Trim

B. Standard Stainless Steel Recessed Handle

Standard in single, double and triple tier wardrobe lockers as well as

Two-Person and Duplex lockers.

C. Single-Point Thru-the-Door Friction Catch and Door Pull

Standard for all box doors.

D. New Latch Hook

Heavier and stronger 12 gauge K.D. latch hook welded to the frame.

E. 6" Legs

Optional at no additional cost, an extension of front vertical frame members.

Rear legs bolted to side and back.

F. Closed Flush Front Base

Optional, ordered with 6" legs. Front bases snap into frame using

no additional fasteners.

G. Hinges

2" 5-knuckle is standard for all.

H. Full Height Door Stiffener

Optional.

I. Continuous Door Strike

J. Clothes Rod

Optional. No additional cost for single tier K.D. lockers 18" or

more in depth.

K. Individual and Continuous Slope Tops

Optional.

1. Standard Louvered Doors

2. Optional Armor Vent security perforations where additional ventilation

is desired,

3. diamond perforations for maximum ventilation or

4. plain (non-louvered) doors for a clean modern look are available

– additional charges may apply. Consult Sales Manager.

K.D. Locker body parts are painted neutral as standard.

Electrogalvanized components are optional.

Locker

Classes

(Locker Body / Duty Scale / Type Construction)

Class 1 (Lightest Duty) to Class

5 (Heaviest Duty)

Class One (1)

Standard Gage K.D. (bolt together) Lockers

, spot-welded frame only -

24 gage bodies, 16 gage doors

Duty Scale - Light

Available Manufacturer's Art Metal Products, List Industries, Inc., Lyon

Metal Products,

Penco Products, Inc., Republic Steel, Worley

(DeBourgh).

Class Two (2)

Heavy Duty Gage K.D. (bolt together) Lockers,

spot-welded frame only -

16 gage bodies, 16 gage doors

Duty Scale - Light to Moderate

Available Manufacturer's Art Metal Products, List Industries, Inc., Lyon

Metal Products,

Penco Products, Inc., Republic Steel, Worley

(DeBourgh).

Class Three (3)

K.D. (bolt together) type construction (parts)

spot-welded together (no body frame,

not multi-column units) Lockers - 16 gage

bodies, 14 & 16 gage doors

Duty Scale - Moderate to Light

Available Manufacturer's Penco Products, Inc, Republic Steel.

Class Four (4)

Uni-body All MIG Welded (multi column units,

no body frame) Lockers - 16 gage bodies,

14 & 16 gage doors

Duty Scale - Moderate

Available Manufacturer's Art Metal Products, DeBourgh Manufacturing, List

Industries, Inc.,

Lyon Metal Products.

Class Five (5)

Full Frame All MIG Welded Lockers - 13 to

16 gage bodies, 14 gage doors

Duty Scale - Heavy

Available Manufacturer's DeBourgh Manufacturing, List Industries, Inc.

|